- Products

- New Materials

- New Material

- In recent years, applications for new materials including structural ceramics and carbon

fiber have expanded in a variety of fields.

These range from state of the art technology in the aerospace industry to common

structural materials.

KYK has developed special equipment for these fields providing higher processing

temperature and more precise atmosphere control.

KYK continues to supply R&D, mass-production, and custom design equipment for these

applications.

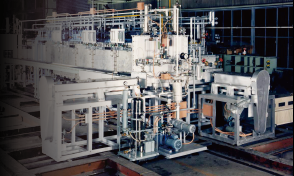

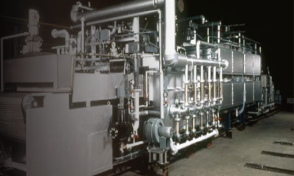

Slot type Carbonization Furnace

(LTF, HTF)

E-GMS-CAB

- Features

- ● Usable for wide range of products from the aerospace to general automotive applications.

● Optimum heater design and material selection results in long service life.

● Precise temperature and atmosphere control results in high product quality and stable

process control.

● Designed to make it easy to perform maintenance work.

● Achieved the world largest production capacity as a single production line.

● Various size of furance are avialable from a tube furnaces up to a 3 meter wide furnace.

- Main applications

- ● Carbonization of fibers, felts, papers, and nonwoven cloths.

- Main specifications

- ● Maximum Temperature: 1800℃

● Atmosphere: Nitrogen, Argon

● Capacity: Laboratory scale up to a large mass production scale.

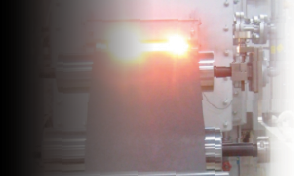

Slot type Graphitization Furnace

(UHTF)

E-GMS-GRA

- Features

- ● Mass production furnace capable of continuously operating at 3000℃.

● Optimum heater design and material selection results in long service life.

● Stable high product quality achieved by the precise temperature and atmosphere control.

● Designed to make it easy to perform maintenance work.

● Heater design to meet the maximum operating temperature.

- Main applications

- ● Graphitization of fibers, felts, papers, and non-woven cloths.

- Main specifications

- ● Maximum Temperature: 3000℃

● Atmosphere: Nitrogen, Argon

● Capacity: Laboratory scale up to a large mass production scale.

Tray-Pusher type

Firing/Sintering Furnace

E-GRP-SIT

- Features

- ● Best suited for heat treatment in a hydrogen and / or inert gas atmosphere.

● Long service life achieved by the optimum heater design and material selection.

● Stable high product quality achieved by the precise temperature and atmosphere control.

● Designed to make it easy to perform maintenance work.

● Capable of continuous heat treatment at 1200℃ or higher.

● Best suited for heat treatment of powder materials in stacked arrangement.

- Main applications

- ● Heat treatment of powder materials.

- Main specifications

-

● Maximum Temperature: 2500℃

● Atmosphere: Nitrogen, Argon

● Capacity: Laboratory scale up to a large mass production scale.

Tray-Pusher type

Pre-carbonization Furnace

E-PSH-PRC

- Features

-

● <Oxidation> Mesh belt oven or Batch type

● <Pre-carbonization> Mesh belt furnace or Batch type

● <Carbonization and Graphitization> Batch type furnace

● Capable of heat treating low strength fibers without applying excessive tension.

● Precisely controlled furnace atmosphere.

- Main applications

- ● Pitch based Carbon fiber Process Short Fiber

- Main specifications

- ● Maximum Temperature: 1000℃

● Atmosphere: Nitrogen, Argon

● Capacity: Laboratory scale up to a large mass production scale.

Mesh belt type

Pre-carbonization Furnace

for Carbon felt

E-MES-PRC

- Features

-

● Non-woven cloth and cloth-like materials can be heat treated on the mesh belt without

applying tension.

● Heat pattern can be easily set to meet production requirements

● Furnace inner atmosphere is maintained clean by reducing exhaust gas.

- Main applications

- ● Mold Insulator

● Carbon Felt

● Carbon Cloth - Main specifications

- ● Maximum Temperature: 1000℃

● Atmosphere: Nitrogen

● Capacity: Laboratory scale up to a large mass production scale.

Heat Treatment Furnace for GDL

E-GMS-CAB

- Features

-

● Non-woven cloth and cloth-like materials can be heat treated on the roll to roll without

applying tension.

● Stable high product quality achieved by the precise temperature and atmosphere control.

● Suitable exhaust process based on each products.

● Designed to make it easy to perform maintenance work.

● Long service life achieved by the optimum heater design and material selection.

- Main applications

- ● Gas Diffusion Layer (GDL)

- Main specifications

- ● Maximum Temperature: 2400℃

● Atmosphere: Nitrogen, Argon

● Capacity: Laboratory scale up to a large mass production scale.

Activation Furnace for ACF

E-MES-ACF

- Features

-

● Heat pattern can be easily set to meet production requirements.

● Furnace inner atmosphere is maintained clean by reducing exhaust gas.

● Large energy saving effects are obtained by utilizing the combustion exhaust gas as

the furnace atmosphere.

- Main applications

- ● Activated Carbon Fiber (ACF)

- Main specifications

- ● Maximum Temperature: 1000℃

● Atmosphere: Steam, Combustion exhaust gas, CO2 gas

● Capacity: Laboratory scale up to a large mass production scale.