- Technologies

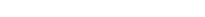

- Salt bath Furnace

Heat treatment in a Salt bath Furnace

●1967 Started sale of Salt bath Furnace.

●1970 Manufactured a large Salt bath Furnace

with capacity of 100 tons.

Despite the decreasing number of Salt bath Furnace

makers, KYK is still providing customers with the

equipment based on the know-how gained since 1967.

Please try KYK's Salt bath Furnaces.

Features of Salt bath Furnace

- 1

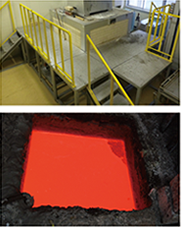

- Heating without contacting air is possible, preventing oxidation and

decarburization.

As the workpiece surface is covered with the salt during transfer from the

furnace to the quench oil bath or water bath, oxidized scale and decarburization do not take place. - 2

- Easy to uniformly heat the whole workpiece.

Easy to control heating temperature by keeping the bath temperature.

Each portions in complicated shapes can be uniformly heated in a short time. - 3

- Easy to support and move the workpiece in the furnace.

- 4

- Partial heating of workpiece is also possible.

- 5

- Extended electrode life by using graphite in the place of regular metal

electrode which is subject to corrosion when used in a salt bath for

brazing.

Main applications

- Quenching of high-speed tool steels.

- Quenching of aircraft parts, brazing of aircraft engine parts, heat exchanger parts,

and aircraft control radar parts. - Brazing of aerospace parts, satellite loaded parts, and high frequency electrical

parts.

Size and Capacity(Width, Length, Height)

| Width | Length | Height | |

|---|---|---|---|

| Graphite electrode | 915 | 1200 | 1390 |

| 915 | 1200 | 1390 | |

| 610 | 610 | 1070 | |

| 400 | 400 | 810 | |

| Metal electrode | 457 | 457 | 1500 |

| 457 | 457 | 3500 | |

| 343 | 343 | 920 | |

| 230 | 230 | 635 |